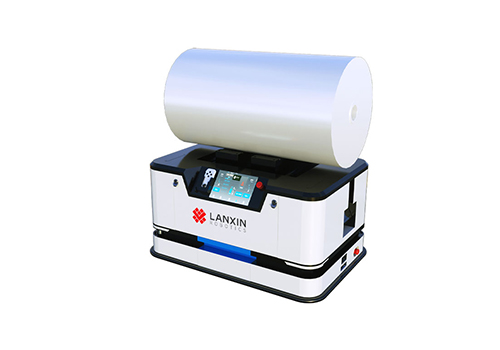

LXLR-FR3300L

This next-gen solution integrates mobile robots and factory automation equipment, enabling collaborative planning and intelligent dispatching. Its core feature, an advanced low-code business process engine, simplifies scenario construction, allowing rapid response to customer needs and quick deployment of customized strategies. This system enhances enterprise

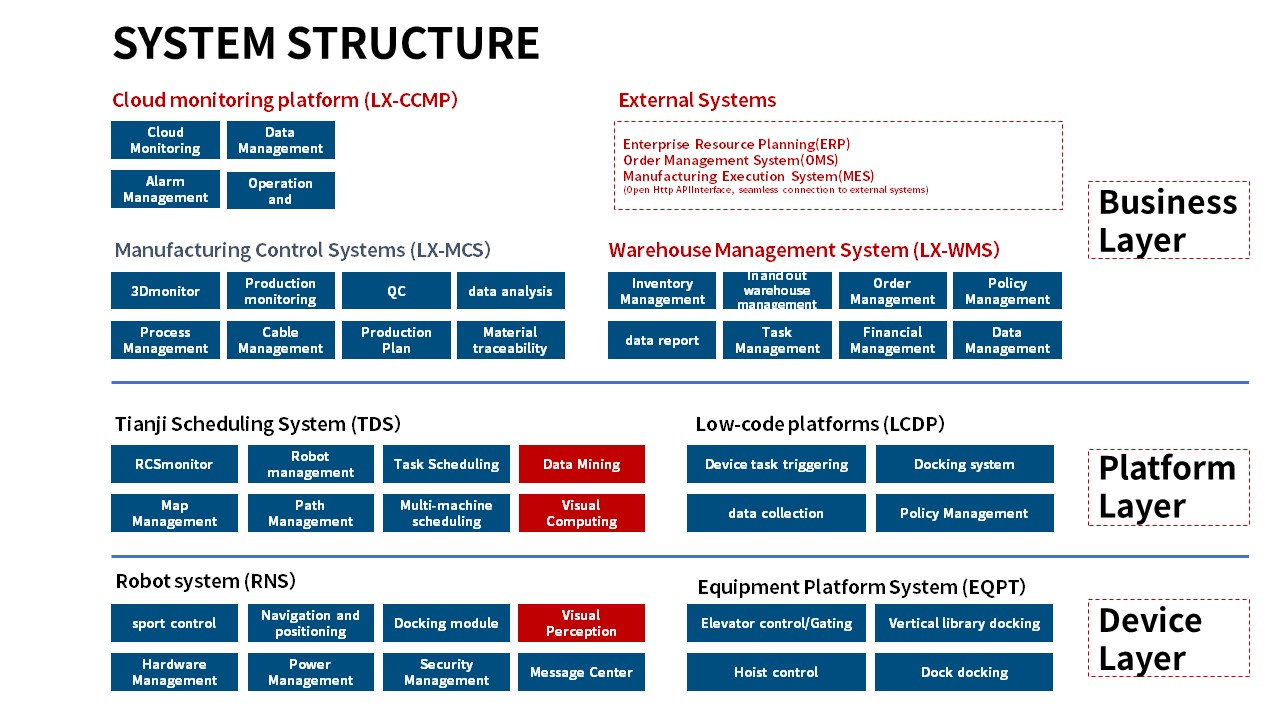

The software system seamlessly integrates the business layer, platform layer, and device layer, achieving comprehensive integrated management. Through a unified data platform and flexible application interfaces, our system efficiently coordinates operations across all levels, ensuring smooth information flow and optimal resource allocation. This comprehensive integration capability not only enhances overall operational efficiency but also strengthens the enterprise's ability to adapt quickly, supporting the realization of intelligent and automated production management.

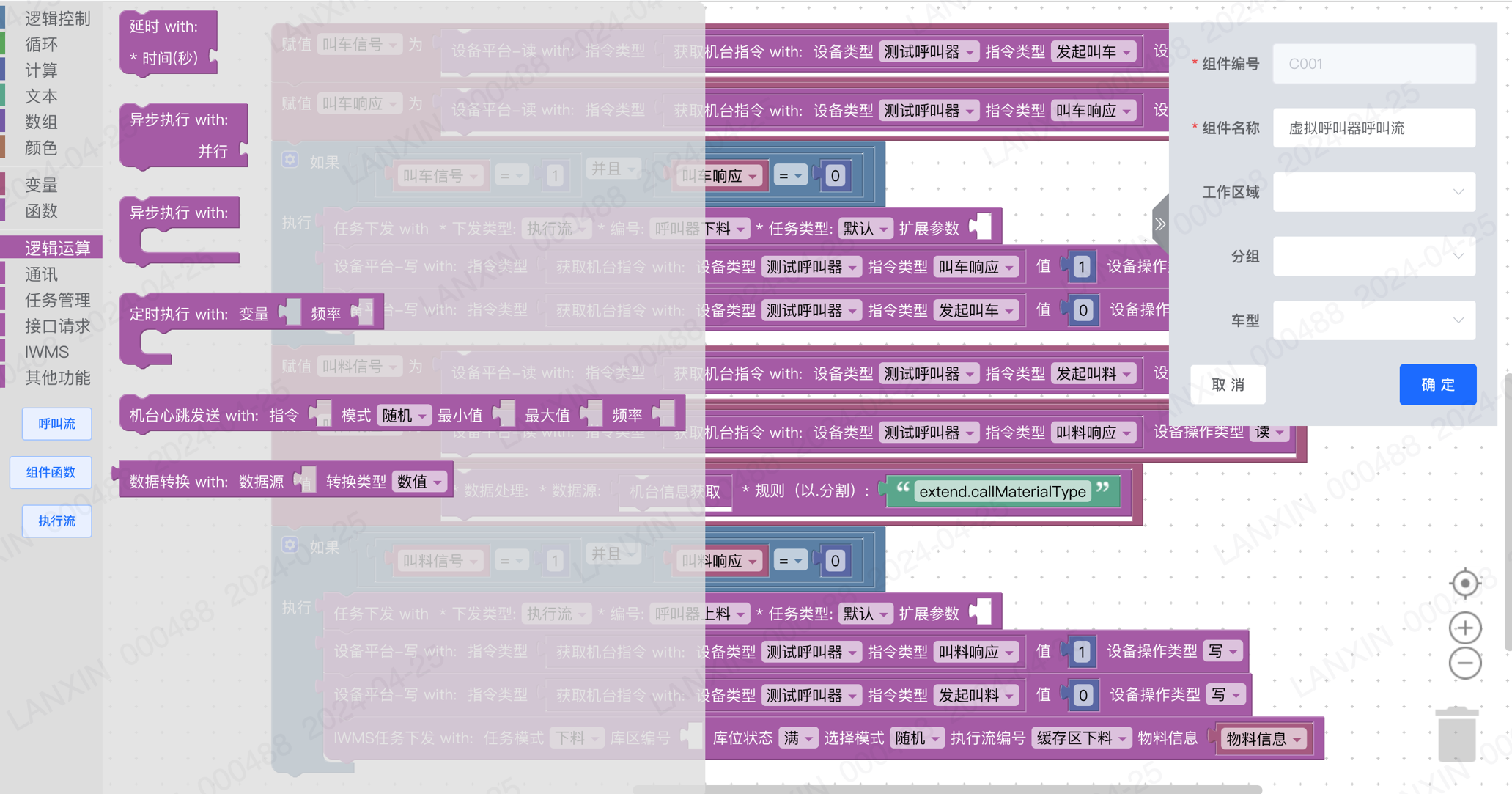

The task interface uses modular assembly for convenience and simplicity, eliminating the cumbersome device configuration process.

Interfaces seamlessly integrates with various facilities such as automatic doors, call boxes, and elevators, achieving intelligent device linkage and control.

The visual dashboard vividly displays the factory map, real-time tracking of robot status, task progress, and material flow details, providing a multi-angle, comprehensive presentation of task data. With millisecond-level real-time response capability, the system promptly pushes alerts and anomaly information, ensuring users have a clear overview of the entire site at all times.

This visual monitoring screen not only meets the diverse needs of enterprises for image presentation, daily factory monitoring, on-site fine management, and real-time operations but also features visual maps and 3D digital twin functions. It builds an efficient and intuitive information display and management platform for enterprises, empowering them to achieve higher levels of digital transformation and intelligent upgrades.

Accurately replicating the real factory scene, it leads the way into a new realm of digital manufacturing.

.jpg)

Contact Us

Lanxin Technology, 7-802,

China Artificial Intelligence Town,

No.1818-2 Wenyi West Road,

Hangzhou, Zhejiang, China

marketing@lanxincn.com

Pouplar Products

Cases